Why install ropes in tarpaulin systems for tippers, trailers and truck containers? But what nonsense !!!

Whatever….

For classic automation systems for curtainsider trucks, the use of steel strands is the most common, this is why some customers are surprised when we explain to them that we use a rope system for our automation of tarpaulin for truck.

There are different advantages to using a rope. It allows to offer superior properties, increased security, a lower price and certain guarantees.

- What are the drifts that we can encounter?

- What is the manpower to provide and the complexity required for the maintenance?

- What if our truck is in extreme conditions in all seasons?

- tensile strength?

- Why did you choose ropes as an innovative solution?

So many questions that we are going to answer now.

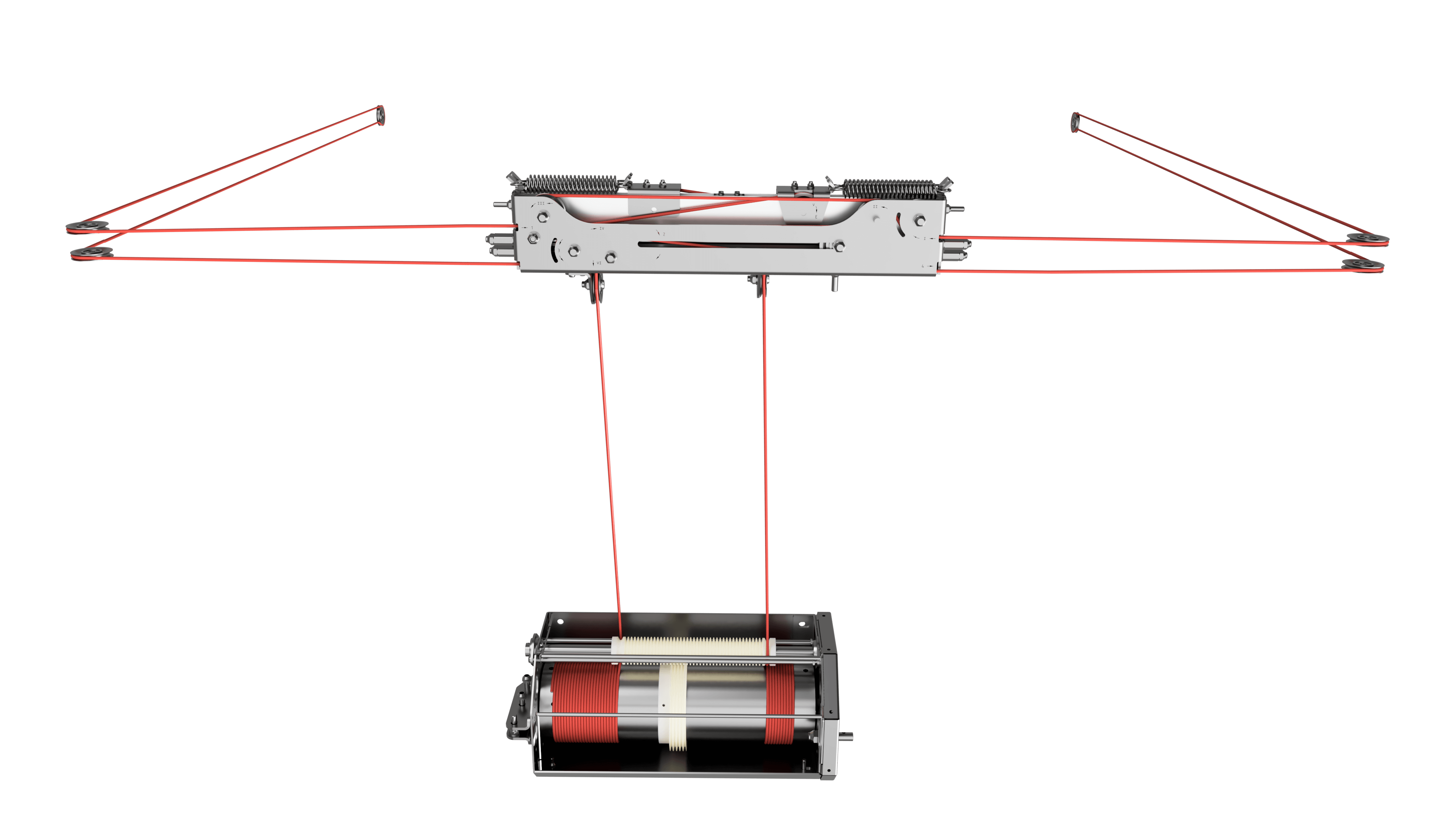

General information on the roping system for truck tarpaulins

Contrary to preconceived ideas, ropes can compete with the steel cables that manufacturers favor.

Indeed if we only take into account the tensile strength , the rope is the best solution. At equal diameter, the rope can withstand up to 3% more traction. For example, for Ø6, the rope holds 2880 Kg while the steel strand tolerates only 2600 Kg.

The tarpaulin system being independent of certain specificities of the truck (moving floors, public works tippers , grain or agricultural tippers ), it adapts perfectly to a wide variety of environments encountered and customers.

Any deviations

Some drifts that we may encounter are the same as those present on braided steel cables. However, others are not applicable to strings.

Basically, the technology used is different. The pulleys necessary for the implementation of the system are too. We install plastic pulleys because they are lighter, smaller and easier to set up.

In addition, changing a rope can be done in 2 hours by 2 people without any unforeseen events.

1- Corrosion resistance

Rope offers corrosion resistance that steel does not; because all metals corrode. A more aggressive environment such as for waste dumpers therefore implies less drift on the ropes of truck tarpaulins.

2- System maintenance

The maintenance of the rope system is easier than that required by a system based on steel strands. The maintenance of the installed rope requires about 5 times less labor to inspect and retighten it than a steel cable.

The adjustment in tension and alignment imposed on the rope system is, on a physical level, the same as for steel strands. However, this does not go wrong very often. The adjustment on a steel cable system is done regularly while for a system with ropes, the adjustment is done about once a year.

Finally, the strings allow perfect symmetry of the hoops. This reduces the efforts to be provided and therefore allows optimal sliding .

3- Deformation

It is to know that the metals have an expansion which varies according to the temperature. This is why a steel cable will be more stretched in the middle of winter (it retracts with the cold) and loose in summer (greater expansion due to high temperatures).

We therefore use a Dyneema SK78 rope because:

- it does not expand or contract,

- it offers electrical insulation,

- it allows a financial gain,

- it offers a lightness which allows a saving of fuel.

The philosophy of saving fuel and therefore reducing pollution is found in all the systems we install.

4- Security

The tarpaulin rope for tipper and semi-trailer also provides additional security and does not require special protection. Unlike a steel strand which breaks, a rope cannot endanger the physical integrity of the users.

The 12 wires that make up the rope have a greater capacity than the 6 wires of the steel strand. This advantage is possible thanks to the difference in weaving between the rope and the steel.

Likewise, the rope also offers resistance to salt and temperature variations. All this makes it possible to have a more secure covered truck.

5- String tension for truck tarpaulin

Our device called T-comp is used to tighten the rope. This device makes it possible to adjust the tension of the rope in the same way as one regulates a steel rope installed on public works skips or waste skips.

It is also used to adjust the orientation of the poles in order to make them perfectly aligned and symmetrical.

The T-comp is composed of a set of pulleys which by their movements vary the tension of the rope. The adjustment of the tension and the length of cord is completely adaptable. Thus, the truck tarpaulins can be made to measure.

To conclude on the truck tarpaulin rope

Our solutions are found in line with the demands of our customers. This is why the strings were favored to the detriment of the steel strands.

All the reasons and features described above convinced us to use ropes. It might sound strange, but all automated systems yield to tradeoffs and we are no exception.

To learn more about our products, do not hesitate to contact us today.

Student in materials and structural design by work-study program